Strong partnerships often define how industries evolve and the relationship between MiTek and Saint-Gobain is a prime example of how collaboration can drive innovation and efficiency across the housebuilding sector.

This partnership spans many years, built on shared values, trust, and a mutual ambition to push boundaries. A key player in this journey is Stephen Mullan, Head of Digital Construction at Saint-Gobain, who has seen firsthand how working closely with MiTek has transformed daily operations.

Embracing PAMIR

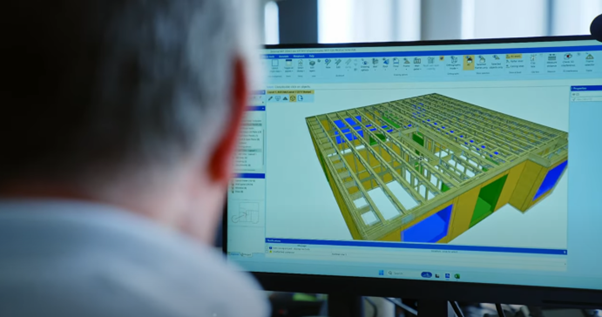

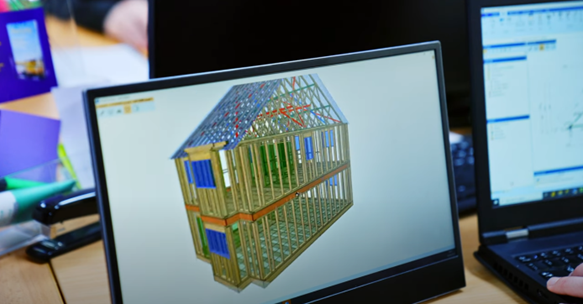

At the core of their collaboration is PAMIR, MiTek’s powerful 3D design software, now used across all 14 of Saint-Gobain’s design offices. For Saint-Gobain, adopting PAMIR was a significant step toward modernising their workflows.

“People at the start couldn’t see the kind of efficiency gains we’d get from it,” Stephen says. “Before, we had to design trusses with one program and use separate software to do a layout. PAMIR integrates both steps together. Now, everyone sees the benefits.”

He describes PAMIR as a comprehensive solution that’s surprisingly easy to learn, helping new team members adapt quickly while still offering the depth needed for complex projects.

“Anybody we’ve employed from different businesses who used other software always say PAMIR is the best, once they get onto it. It’s a massive piece of software that covers everything you want it to do. But it’s strangely easy to learn the basics and get yourself going.”

Connecting Saint-Gobain businesses

The benefits go far beyond software performance. The partnership enables seamless collaboration between Saint-Gobain’s businesses, from truss design at Pasquill to manufacturing at Scotframe, and even roof panel production at Roofspace.

Stephen explains that PAMIR’s ability to integrate wall design is unlocking new possibilities:

“Once we get the PAMIR Wall journey complete, we’re closer to our goal of having whole-house designers in the business. We’ll only be able to do that because of PAMIR.”

Expanding careers and unlocking efficiencies

The shift towards whole-house design has also made it easier to train and develop talent. Designers who once focused solely on trusses are now expanding into wall panels, floors, and roofs, all within a single software environment.

“It’s making it easier to train and upskill people. We’ve got timber frame designers asking to do their own floors and roof trusses now. People can advance their careers faster.”

Efficiency improvements ripple through every part of the business, from the design studio to the job site. PAMIR’s integrated 3D modelling reduces risks and errors, saving both time and cost.

“A designer and a manufacturer can both look at the same file at the same time and collaborate more easily,” Stephen explains. “You’re taking away the risk of problems because your 3D models are all tied together, and you’re able to check everything collaboratively. It all fits like a glove.”

Benefits for clients too

The positive impact even extends to Saint-Gobain’s clients, who appreciate the modern approach. Using digital models and tools like QR codes, teams can share clear, precise information quickly, eliminating the back-and-forth traditionally required to clarify paper-based designs.

“Clients think it’s amazing. We use QR codes to send out 3D models. Anything that wouldn’t be clear on old-style paperwork, they can now check digitally. That’s real efficiency. It might seem small, but those few emails to check a dimension stack up. What used to take half an hour now takes one minute.”

A digital future

Looking to the future, the collaboration between MiTek and Saint-Gobain shows no signs of slowing down. Both companies are working closely on MiTek Optics, MiTek’s next-generation cloud-based business platform. While still in development, Stephen is excited about its potential.

“Optics isn’t ready for us yet. We’re very demanding in terms of what we need, but it’s going to be great when we get it. We’ll see another efficiency boost from moving to cloud-based software.”

Saint-Gobain has big ambitions for a digital factory, where tablets replace paperwork and every production detail is visible in real time.

“We want people walking around with one tablet instead of stacks of paper,” Stephen says. “If a customer calls and asks how their truss is getting on, we want to say exactly where it is in the process. It’s like Amazon tracking for construction. And for a big company like Saint-Gobain, it’s also about being greener.”

Both MiTek and Saint-Gobain know that the journey toward a fully digital future won’t happen overnight, but their shared vision is clear. Together, we’re proving that with the right technology and the right people, the future of timber construction can be smarter, faster, and more sustainable.

Could MiTek help your business operate more efficiently and grow faster? Start the conversation with us today.